|

| |

| |

|

| |

| |

|

|

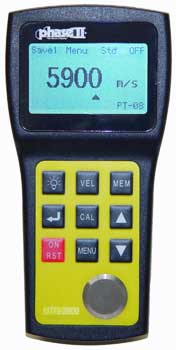

| Ultrasonic Thickness Gauges |

State

of the art, digital ultrasonic

thickness gauge is capable of reading

wall thickness thru coatings and paint without affecting

the measurement and is packed with the most popular

features including basic measurement, Scanning Capabilities,

Adjustable Sound Velocity, extended memory and USB

output capabilities. This dynamic ultrasonic

thickness gauge is

designed to measure the thickness of metallic and

non-metallic materials such as steel, aluminum, titanium,

plastics, ceramics, glass and any other good ultrasonic

wave conductor as long as it has parallel top and

bottom surfaces. The UTG-2600 ultrasonic

thickness gauge will accurately display

readings in either inch or millimeter after a simple

calibration to a known thickness or sound velocity. State

of the art, digital ultrasonic

thickness gauge is capable of reading

wall thickness thru coatings and paint without affecting

the measurement and is packed with the most popular

features including basic measurement, Scanning Capabilities,

Adjustable Sound Velocity, extended memory and USB

output capabilities. This dynamic ultrasonic

thickness gauge is

designed to measure the thickness of metallic and

non-metallic materials such as steel, aluminum, titanium,

plastics, ceramics, glass and any other good ultrasonic

wave conductor as long as it has parallel top and

bottom surfaces. The UTG-2600 ultrasonic

thickness gauge will accurately display

readings in either inch or millimeter after a simple

calibration to a known thickness or sound velocity. |

| |

Specifications:

|

Model No. UTG-2600 |

Display type |

4-digit LCD w/Back Light |

Minimum display unit |

0.003 (if>3.93”

0.0003” (if<3.93”) |

Measuring Range |

Standard Mode: 0.040" to 12" in

steel

Thru Coating Mode: 0.118” - .905” 3.0 -23mm)

w/standard probe |

Accuracy |

+/- 1%xH + 0.0007” (H=displayed

value) |

Sound velocity range |

3280-32805 ft/s (1000-9999m/s) |

Upper/Lower Limit Preset

Alarm |

Yes |

Operating temperature |

32-122 degrees F |

Frequency |

4MHz |

Update range |

4Hz |

Memory |

500 Test Values |

Output |

USB |

Mini-Printer |

Optional |

Power supply |

3v AA alkaline batteries (2pc) |

Battery life |

Approx. 100 hours (w/backlight

off) |

Power consumption |

Working current is less than

3V |

Dimensions |

5.86” x 2.87” x

1.25” (149 x 73 x 32mm) |

Weight |

5.6oz (160g) |

UTG-2600 ultrasonic

thickness gauge comes complete

with Certificate of Calibration, Operation

Manual and Custom Carry Case. |

ULTRASONIC WALL THICKNESS GAUGE MEASUREMENT

The use of Ultrasonic non-destructive testing (NDT) to check material properties such as thickness measurement, is now extensively used in all facets of industry. The ability to gauge thickness measurement without requiring access to both sides of the test piece, offers this technology a multitude of possible applications. Metals, plastics, ceramics, glass and other materials can easily be measured by portable ultrasonic thickness gauges with a common accuracy of.001”.

Ultrasonic thickness gauges measure the thickness of a part by measuring the time sound travels from the transducer through the material to the back end of a part, and then measures the time of reflection back to the transducer. The gauge then calculates the thickness based on the velocity of sound through the material being tested.

A broad variety of piezoelectric transducers, operating at given frequencies are utilized to generate sound when excited. Typically, a 5mhz frequency is standard on all Phase II Ultrasonic Thickness Gauges. Optional transducers are always available for a myriad of applications.

The direct contact method of pulse/echo type ultrasonic thickness gauges requires use of a couplant. Propylene Glycol is common, but many other substances can be used.

Easy to configure and use, many gauges today have the ability to retain memory, output to printers, PC’s, and handheld portable devices. With the combination of an easy menu driven gauge and the data in memory, technician/operators have a world of technology at their fingertips to obtain highly accurate and cost effective measurements for all types of thickness applications. |

|

|

| ULTRASONIC THICKNESS GAUGE LINKS |

|

| TRADE SHOWS |

- China Electronics Fair-Shenzhen - Booth 1B157 - Shenzhen

Convention & Exhibition Center - April 9, 2010-April

11, 2010

- IMTS 2010 - Booth E-5217 - Lakeside Center, McCormick

Place, Chicago IL USA - September 13, 2010 - September

18, 2010

|

| |

|

|

|

|

| |

| |

| |

| |

|

|